Clean a potentiometer

How to clean a potentiometer properly

First I want to preface this by saying there are a few reasons that a pot can sound scratchy. First is there is DC flowing through the pot. Some circuits are just poor designs that have DC on the wiper by design; others it's a leaky coupling cap causing DC on the wiper. In the former it's a case of replace the pot and add a suitable cap; in the latter it's a case of replace the pot and the faulty cap.

Secondly, the pot can be genuinely worn out through age and use, so again needs to be replaced. If a pot is scratchy, cleaning it is at best a stop-gap measure - not a repair. In some cases where dirt can get into a pot easily (i.e. the old Crybaby wah), cleaning is a viable option.

Ever notice that when you clean a potentiometer (referenced as "pot" from now on) it gets all loose when it was nice and smooth before you cleaned it? It's because you are cleaning your pots wrong. In our small world of guitar pedals and amps we tend to just shoot any old electronics/contact cleaner in a pot, give it a few spins, and it's good to go. Well, you really can be making more of a mess than anything. When you spray a "cleaner" into a pot, you are dissolving the damping grease in the pot shaft. This grease gives it that firm, smooth feel and also keeps dust and moisture from entering the pot through the slot around the shaft. This grease you just dissolved can also get all over inside the pot. Some contact cleaners even damage the carbon resistance element inside the pot. Most “contact cleaners” are trichloroethane, an industrial solvent, which destroys typical pots quickly. It may function for a short time but the loss of lubricant is a life-ending condition. Most of these products are meant for switches and plug/socket connections. It's important to read the white papers/technical information sheets for the product you intend to use.

The best way I've found to clean a pot is to take it apart. Once apart you can carefully clean the contacts and the resistive strip without doing too much to the grease. There are a few products that I've found to work the best for cleaning. The "best" one I've found is Nu-Trol Control Cleaner. DeoxIT D100 is pretty good also and probably the best one to use IF you had to just spray something into the pot as it doesn't seem to dissolve most shaft greases.

Cleaning The Pot:

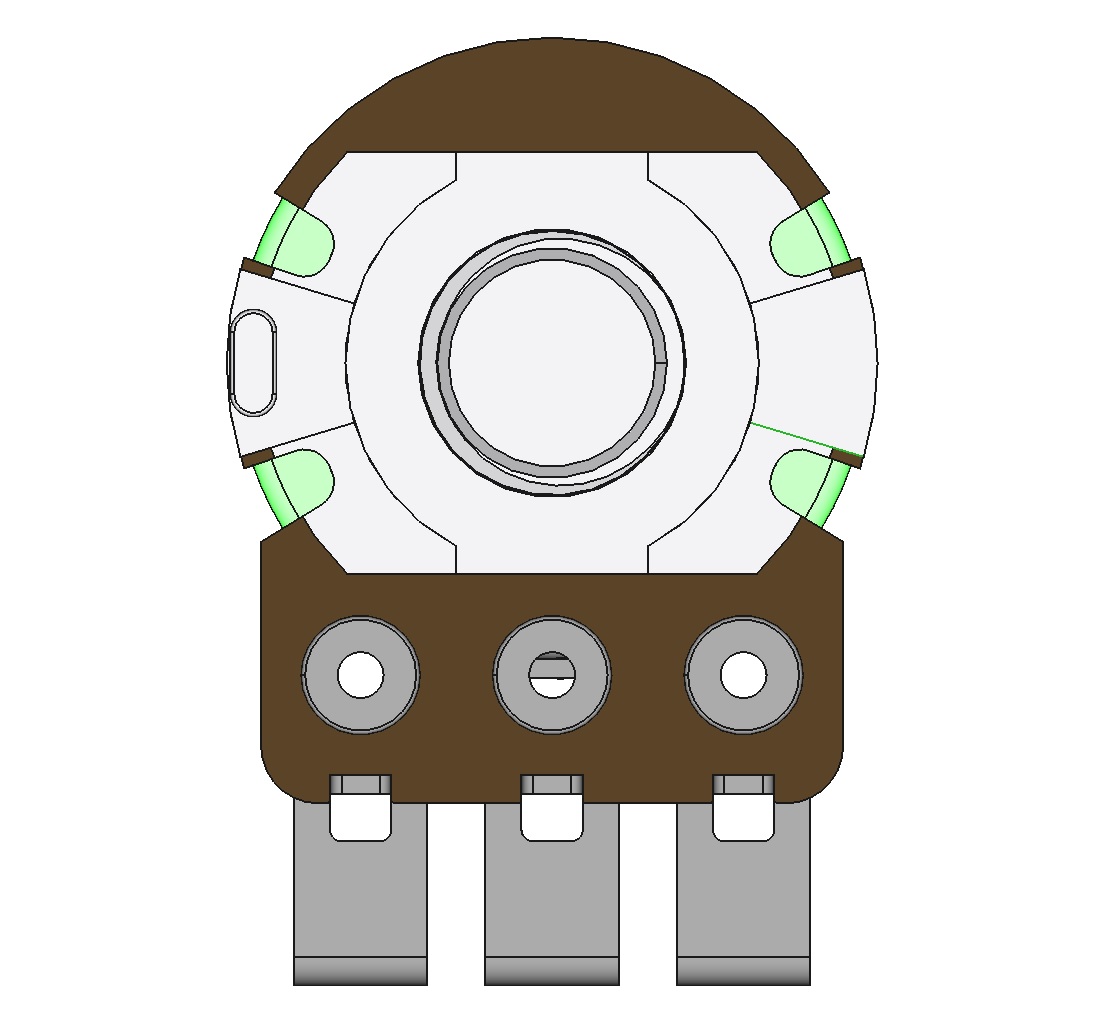

Not all pots can be cleaned. Some are sealed and you would have to drill out rivets to open it and then reassembling it is near impossible. It's best just to replace this type. Now some pots you can open by prying some tabs open and removing the back. In the image below the tabs are highlighted in green. Once the tabs are lifted, you should be able to disassemble the pot.

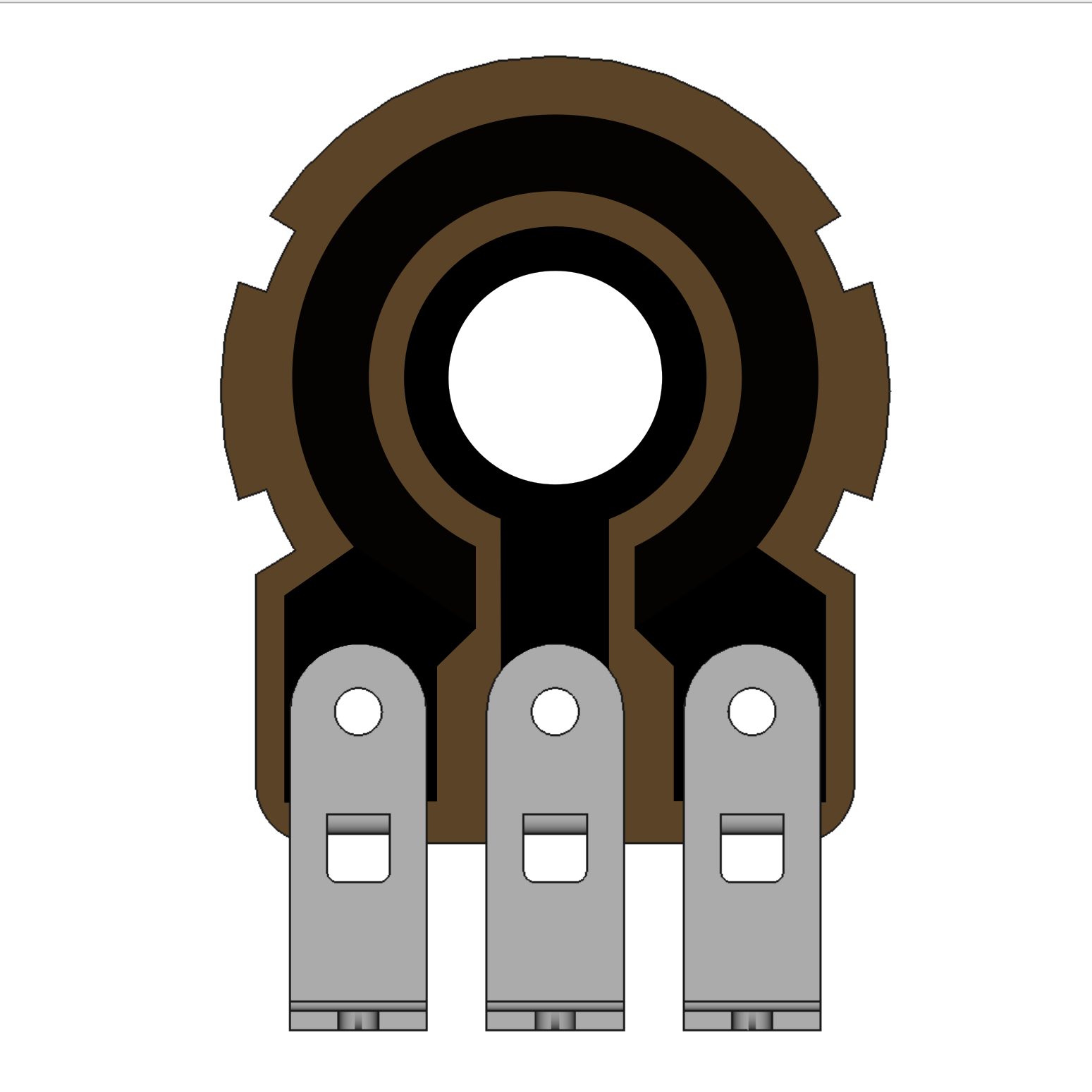

Once disassembled, you will want to clean the pot wafer and it's resistive strips. The resistive strips are shown in black below and are usually black-ish in a pot as they are usually carbon. There are two strips. One on the wiper (center leg) and one connecting the outer legs. You'll want to take your cleaner and carefully clean the strips and wafer. Sometimes I use a Q-tip but make sure not to leave any Q-tip fibers on it. Using a lint-free cloth is probably better.

OK. Now you cleaned it. What if your pot has that loose feel because you sprayed a cleaner in there or you just want to replace the grease that was on there? I'd take a cloth/paper towel and wipe off as much grease as you can. Then I would apply new grease to the shaft but only apply it slightly above where the shaft is going to be exposed when put all back together. You don't want to put so much on that when it's back together it gets all over the wafer. When you put it back together, the grease should spread along the shaft as you slide it through the threaded part of the body. You can wipe up any exposed grease on the shaft.

The grease I found to work best is DeoxIT Fader Grease. I've also used a lithium grease and it worked just as well. It does need to be a non-conductive grease. Rheolube 716A is another expensive option. I've used it at a job I had and it works really well.

Now just put the back of the pot on and bend the tabs back in place.